SMD or DIP LED Which Works Best for You

Time : Dec 04, 2025 View : 359

Navigating Display Technology: Understanding the Fundamentals

Picking the right kind of LED display can make or break a product. A cheap kitchen scale that’s hard to read in the morning light feels frustrating. A charging station for electric cars that stays bright and clear in the rain feels trustworthy. The difference often comes down to one simple choice: do you go with Surface Mount Device (SMD) LEDs or the older Dual In-line Package (DIP) style? Both have their place, and knowing the real-world strengths of each helps you pick the one that fits your job.

The Landscape of LED Display Technologies

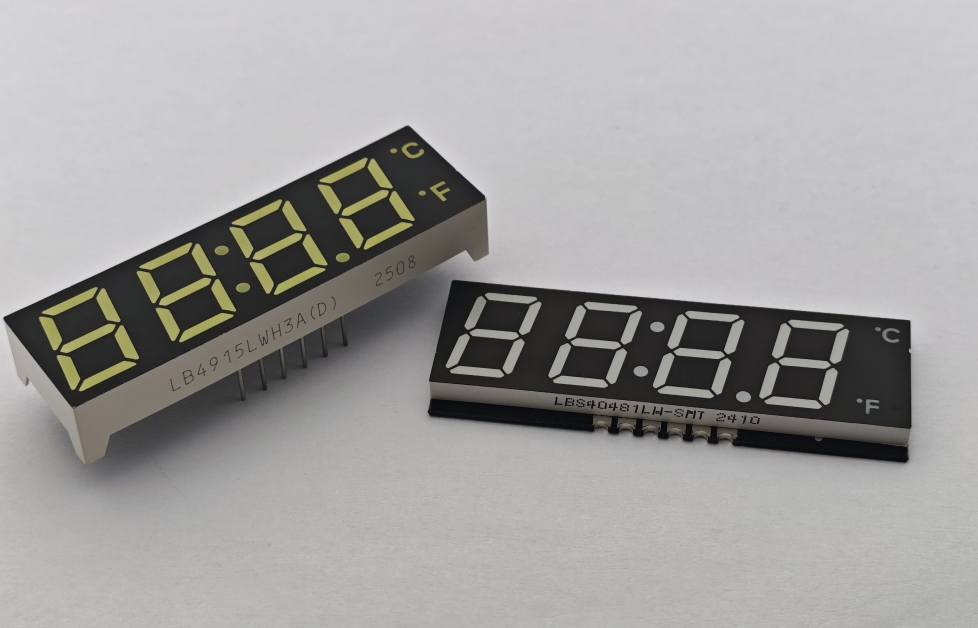

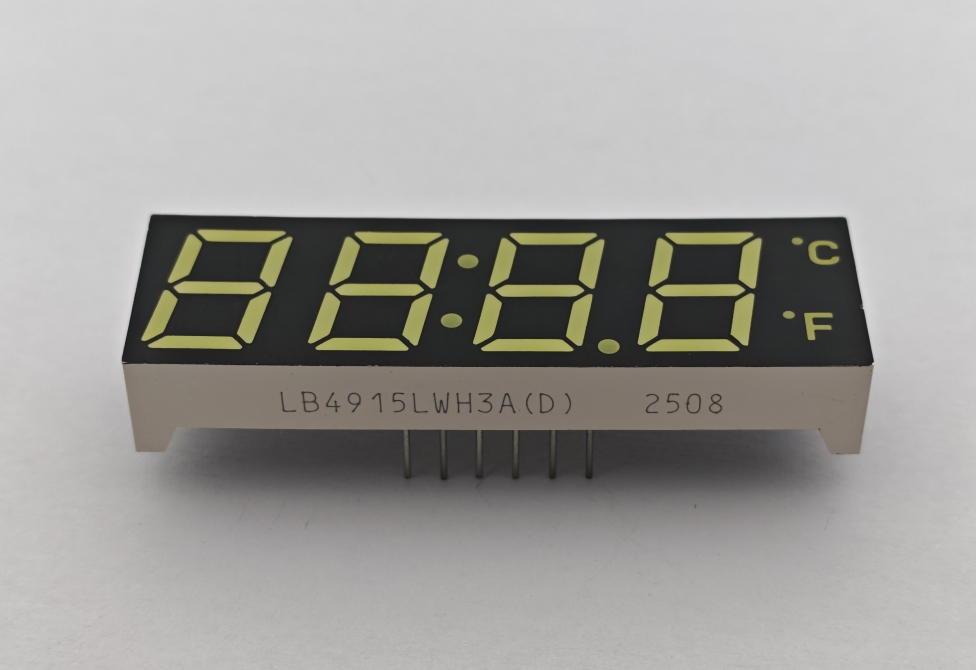

Walk into any factory that makes ovens, refrigerators, or power meters, and you’ll see the same basic building blocks: 7 Segment LED Display units for numbers, Dot Matrix LED DISPLAY panels (16×16, 8×8, 5×8, 5×7) for letters or simple icons, and sometimes Alphanumeric LED Display modules when you need both. Some boards use tiny SMD chips soldered flat to the surface. Others still use the classic DIP LEDs with two legs pushed through holes in the board. Both get the job done, but they behave differently once they leave the factory floor.

Key Distinctions in LED Display Architecture

The way the little light chip is packaged changes everything from how bright it looks outdoors to how long the whole unit lasts in a hot factory.

Surface Mount Device (SMD) Technology

SMD LED Displays are flat and small. The chip sits right on top of the circuit board and gets soldered in place by machine. This style has taken over most new designs for good reasons.

What you actually notice with SMD in daily use:

- They pack more lights into the same space. A 0.8-inch-tall 7 Segment LED Display can still show crisp digits even when the whole thing is barely bigger than a postage stamp.

- You can read them from the side without the numbers washing out. Stand next to a modern washing machine and the time stays readable – that’s SMD doing its job.

- Colors stay even across the whole screen. When an oven display switches from red to green to white, every segment looks the same shade.

- Factories love them because giant pick-and-place machines can drop thousands of chips per hour with almost no mistakes.

Dual In-line Package (DIP) Technology

DIP LED Displays still have the two long metal legs you probably remember from old electronics kits. The legs go through holes in the board and get soldered on the back side. People have used this method for decades, and it refuses to disappear for solid reasons.

Real advantages you feel on the job site:

- They laugh at vibration and heat. A DIP display on a construction-site multimeter can bounce around in a toolbox for years and still work.

- Raw brightness is hard to beat. On a sunny day, a big outdoor scoreboard made with DIP LEDs cuts through glare better than most SMD screens of the same size.

- If one light ever dies, a technician with a soldering iron can swap it in minutes. Try that with a surface-mount chip, and you’ll need hot-air tools and steady hands.

- The plastic bulb around each DIP LED acts like a little raincoat. Dust and splashes don’t stand much chance.

Tailoring Solutions: When Technology Meets Application

There is no single “best” answer. The right choice depends on where the display has to live and what it has to survive.

Versatile Product Applications

Our own boards end up in all kinds of places. In kitchens, the 3-digit 12.7mm 7 Segment LED Display sits behind the glass door of refrigerators and tells you the exact temperature at a glance. In electric-vehicle charging posts, bright white or pure green digits stay readable even when snow is blowing sideways. Inside factory control panels, red Dot Matrix LED DISPLAY units scroll warnings or production counts hour after hour without fading.

The Power of Customized Solutions

Off-the-shelf parts only take you so far. When a customer needs something special, we roll up our sleeves.

Here’s what usually happens:

- An engineer calls and says the new air-fryer display has to be ultra-bright white but still fit inside a 9 mm high cavity. We pull out the drawing board, pick the right SMD chip height, and build a sample in two weeks.

- Another buyer wants a UPS system that flashes different colors for different battery levels. We take a standard 7 Segment LED Display, swap in multicolor chips, and write the simple drive code ourselves.

- A power-plant customer once asked for Arrow LED DISPLAY bars that could survive steam and chemical splashes. We went back to DIP packaging, added thicker epoxy lenses, and sent units that are still running five years later.

All of this is possible because we keep a full workshop with the latest automatic placement machines, wave-soldering lines, and a clean room for final testing.

LIGHTBO: A Commitment to Customized Excellence

LIGHTBO started back in 2006. From day one, the idea was simple: make displays that help our customers sell more of whatever they build. We focus on the parts that light up and show information – nothing else. That narrow focus lets us react fast when someone needs a new size or a tougher version.

Our Advanced Display Offerings

Day to day, we ship:

- Plain 7 Segment LED Display in heights from 0.28 inch all the way to 8 inches.

- Dot Matrix LED DISPLAY boards in the common 5×7, 5×8, 8×8, and 16×16 layouts, plus odd sizes when asked.

- LED backlight panels for LCDs.

- Light bars, arrow shapes, and complete multifunction modules that already include the driver chip and touch buttons.

Quality, Development, and Manufacturing Advantages

- HIGH QUALITY

Every finished board leaves the line only after passing a full burn-in test and optical check. We run our own professional test lab and keep paperwork for RoSH, Trust Seal, and every credit check buyers ask for.

- DEVELOPMENT

Eight full-time engineers sit ten meters from the production floor. When you send a rough sketch on Monday, they usually have a working sample by Friday.

- MANUFACTURING

Rows of high-speed machines place up to 120,000 SMD chips per hour. The DIP lines still run every day, too, because some jobs still need those tough old-style LEDs. Strict checklists at every station mean the reject rate stays under one part in a thousand.

We keep putting more money into new tools and training. The goal is always the same: ship perfect parts on time so your assembly line never stops.

FAQ

Q: What industries primarily use LIGHTBO’s display devices?

A: You’ll find our parts in household appliances (especially ovens, refrigerators, and air conditioners), new-energy charging equipment, factory instruments, and power-supply units. We’ve been the go-to supplier for kitchen-appliance readouts for years.

Q: What specific display types does the company manufacture?

A: We build 7 Segment LED Display, Dot Matrix LED Display in all common sizes, Alphanumeric LED Display, multifunction modules with touch, LED backlight sheets, light bars, arrow indicators, and full SMD LED DISPLAY assemblies.

Q: What evidence supports the quality of LIGHTBO’s products?

A: Independent RoSH certification, Trust Seal reports, on-site credit checks, and a professional test lab that checks every batch for brightness, color, and life span.

Q: How does LIGHTBO support customized product requirements?

A: We assign an engineer to your project from the first call. That person stays with you through drawings, samples, testing, and final production – all inside our own factory, so changes happen fast and stay under control.