Key Advantages of Surface Mount Devices for PCB Technology

Time : Jan 02, 2026 View : 239

Introduction: The Miniaturization Imperative

Electronics keep getting smaller, quicker, and stronger. Older Through-Hole Technology (THT) no longer fits most needs. Surface Mount Devices (SMD) now lead the way in Printed Circuit Board (PCB) work. This change has reshaped how people build circuits and make products. It allows tight packing for today’s gear—from factory tools and new energy setups to slim items like e-cigarettes. Knowing the main benefits of SMD helps any builder stay ahead. This piece covers the practical gains of SMD. It also shows how companies like LIGHTBO, focused on LED display parts, use this method to supply small, reliable visual units, including our SMD LED DISPLAY line.

Defining the Shift: SMD vs. Through-Hole Technology (THT)

The Core Concept of Surface Mounting

Surface Mount Technology (SMT) places parts—the Surface Mount Devices (SMD)—right on the PCB top. Leads do not go through holes. THT sends leads all the way through the board. That takes up room and limits spots. SMD parts are soldered to surface pads instead. This cuts the size and opens more layout choices.

Enabling Density and Miniaturization

Shrinking size drives SMD use. Current items, such as home units like ovens and fridges, plus small new energy gear, need more circuits in tight spots. SMD skips leads and holes. Parts sit closer, and both board sides work. This dense setup supports portable, loaded devices today.

Key Advantages of SMD for PCB Design and Manufacturing

Switching to SMD helps from the drawing stage to full runs.

Increased Component Density and Board Space Optimization

SMD cuts size most clearly. These parts are far smaller than the THT ones. More fit on the board.

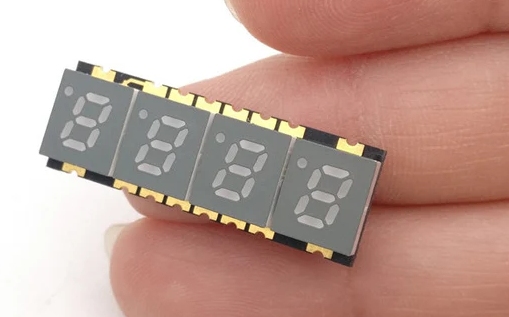

Smaller boards save material and suit thin cases. For display makers like LIGHTBO, SMD brings tiny units—think the Multicolor Ultra Thin Custom 7 Segment LED Display Cathode For E-cigarette—where thickness and room matter most.

Enhanced Electrical Performance

SMD improves signals beyond size, especially in fast or radio-frequency work. Short or no leads drop extra resistance, capacitance, and inductance.

This means:

-

Cleaner signals: Less noise and loss.

-

Quicker operation: Key for digital speed.

-

Better heat flow in some cases: Direct pad to board copper.

In factory and tool uses needing exact signals and quick action, SMD raises dependability and precision.

Streamlined and Automated Manufacturing Processes

SMD fits machines well for big runs and low cost. THT often needs handwork or slow tools. SMD comes on reels for fast pick-and-place robots.

LIGHTBO gains from this in making. We stress MANUFACTURING strength with Advanced automatic machines and a strict process control system. Machines build SMD LED DISPLAY items evenly and quickly. That lowers mistakes and raises output.

Integrating SMD Technology into Display Components

The Evolution of LED Displays to Surface Mount

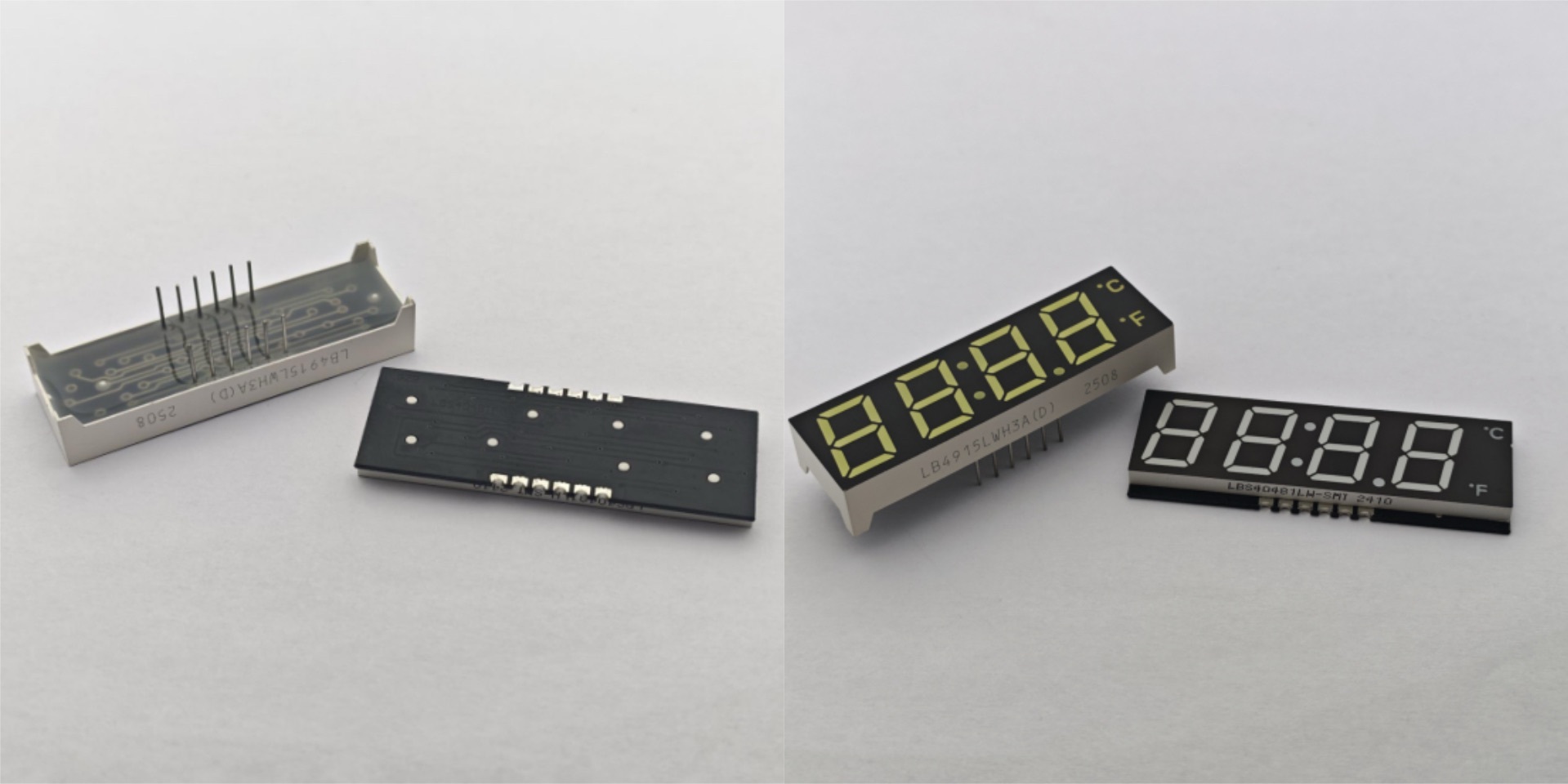

LED displays follow the electronics trend to surface mount. Older types, like some through-hole 7 Segment LED Displays or Dot Matrix LED Displays, use big packages and long pins. SMD versions join the machine assembly line. The display fits more easily into crowded boards.

This helps simple lights to full status screens for UPS systems blend into small layouts.

LIGHTBO’s Commitment to SMD LED DISPLAY Solutions

LIGHTBO sees SMD importance in current designs. We handle R&D, making, and sales of display parts. Our dedicated SMD LED DISPLAY line helps buyers in tough fields like home units, tools, and new energy get size and speed gains without losing display quality.

Many products, from standard 7 Segment LED Display to Dot Matrix LED Display, use SMD inside, even with custom outer cases. This keeps light sources strong and well placed.

LIGHTBO: Leveraging SMD for Quality and Customization

LIGHTBO started in 2006 as a top LED display maker. We focus on quality and new ideas. The guiding idea “Pursuing Excellence, Building Success Together” pushes us to supply advanced custom items.

Ensuring Precision Through Advanced Manufacturing

Small SMD parts demand tight accuracy. LIGHTBO meets this with core strengths:

HIGH QUALITY: A strict quality control system and professional test lab keep standards, including RoSH. This matters for tiny parts in long-use tools and units.

MANUFACTURING: Advanced automatic machines and a strict process control system place and join small display chips.

Customization to Meet Compact Application Demands

SMD flexibility aids LIGHTBO in custom work (DEVELOPMENT). Our in-house design team and modern shop tools let us team up with buyers for exact size and performance fits.

When off-the-shelf displays are too big, SMD packaging allows special builds:

-

Customization: We make items for particular needs, like specialized 7 Segment LED Displays for fridges (Customized White/Pure Green/Blue), or custom units for UPS (Multicolor customization 7 Segment LED Display).

-

Practical gains: SMD helps buyers cut size and costs. Products compete better in big fields like home gear and temperature controls.

Conclusion: The Future of Compact Electronics

Surface Mount Devices form the base of current PCB methods. Their gains in size, performance, and speed are vital for small electronics now. Builders wanting dependable, room-saving displays should choose specialized SMD parts. With careful testing and exact making of SMD LED DISPLAY items, plus strong focus on quality and customs, LIGHTBO helps buyers add top visual parts to their smallest, most advanced builds.

FAQ

Q: Why is SMT generally preferred over THT for mass production?

A: SMT allows for complete automation using pick-and-place machines, resulting in faster assembly speeds and lower manufacturing costs per unit compared to the slower, less automated processes typically required by THT components.

Q: Do SMD components handle heat dissipation better than THT components?

A: In many cases, yes. The lack of long leads allows the thermal pad on the SMD component to transfer heat more effectively directly into the PCB copper layers.

Q: What types of LED displays does LIGHTBO offer in an SMD format?

A: LIGHTBO offers a dedicated category of SMD LED DISPLAY, and can also apply surface mount techniques to various display types, including 7 Segment LED Display, Dot Matrix LED Display, and Alphanumeric LED Display, depending on the application requirement.

Q: How does SMD affect the reliability of the finished PCB?

A: SMD connections are generally more robust against vibration than THT components, offering high reliability, especially when manufacturing quality is maintained through strictly controlled processes and professional testing, as ensured by LIGHTBO.