How to Professionally Test 7-Segment LED Display Performance

Time : Jan 15, 2025 View : 1,419

In a wide range of electronic devices, the 7-Segment LED Display plays an indispensable role with its simple and intuitive way of displaying numbers. From the most basic digital clocks and calculators to complex industrial meters and home appliance control panels, its stable and reliable characteristics have earned it widespread use. However, to ensure product quality and user experience, it is crucial to professionally test the performance of 7-segment LED displays. This article will introduce a systematic testing methodology to help you comprehensively evaluate its performance.

I. Core Performance Indicators

1. Brightness and Uniformity

- Brightness:Refers to the brightness of each illuminating segment, usually measured in millicandelas (mcd) or nits. High brightness ensures clear visibility in various ambient light conditions.

- Uniformity:This is a particularly important indicator for 7-segment LED displays. It requires all segments that form a number or symbol to have consistent brightness under the same driving conditions. Poor uniformity can make the displayed numbers appear “incomplete” or unevenly lit.

2. Chromaticity and Color Consistency

- Chromaticity:Measures the purity of the display’s emitted color. Even for colors like red or green, there may be color shifts. Professional chromaticity testing can ensure the product meets the specified color standards.

- Color Consistency:In multi-digit displays, in particular, the color of all displays should be highly consistent. Inconsistent colors can significantly detract from the visual aesthetics and professionalism.

3. Response Speed

- Response speed refers to the time it takes for a segment to fully light up after receiving an electrical signal. While the response speed of 7-segment displays is typically very fast (nanoseconds), a slow response in high-speed dynamic or scanning-driven applications can lead to ghosting or brightness reduction.

4. Reliability and Durability

- Lifespan:The lifespan of an LED light source is usually long, but its performance can be affected by high temperatures, high humidity, or frequent on-off cycles.

- Temperature Resistance:Industrial and outdoor equipment requires displays that can operate normally within a wide temperature range.

- Vibration Resistance:In vehicle or mechanical equipment, vibration resistance is key to ensuring the stable operation of the display.

II. Professional Testing Methods

1. Subjective Testing (Visual Inspection)

- All-Segment Test:Light up all segments (a to g and the decimal point) simultaneously and observe for any dead segments or noticeable brightness inconsistencies. This is the most basic quality check.

- Number Cycle Test:Cycle through numbers 0 to 9 sequentially, checking that each segment turns on and off properly and that there is no “ghosting” or flickering.

- Multi-Angle Observation:Observe the display from different angles to assess its visibility. A good display will remain clear over a wide viewing angle range.

2. Objective Testing (Using Professional Equipment)

- Luminance Meter / Colorimeter:These are the primary testing tools. By measuring multiple points on each segment, you can get precise data on brightness, chromaticity, and color temperature and compare them against standards.

- Oscilloscope:In dynamic drive mode, an oscilloscope can measure the rise and fall times of the segments to evaluate their response speed.

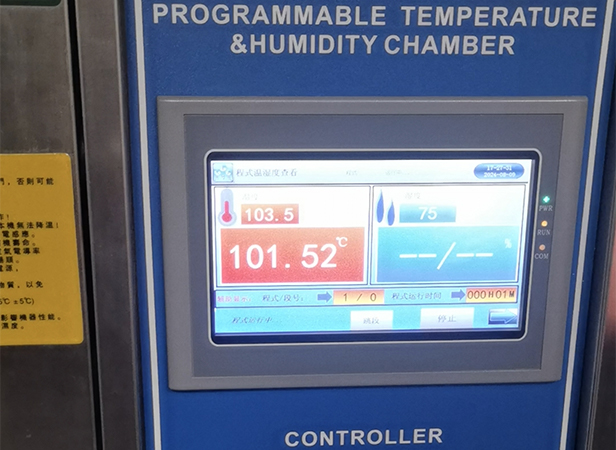

- High/Low Temperature Chamber / Vibration Table:Place the display in a high/low temperature chamber or on a vibration table for performance testing. Test its brightness and display stability under extreme temperatures or continuous vibration.

- Spectrometer:For applications with very high color requirements, a spectrometer can be used to test the spectral characteristics of the display to ensure its color purity.

III. Conclusion

Although the 7-segment LED display has a simple structure, its performance is directly related to the quality and reliability of the final product. By combining visual inspection with professional equipment testing, you can comprehensively evaluate key indicators such as brightness, uniformity, and color consistency, providing a reliable basis for product selection, quality control, and technical improvements.

Would you like me to provide a more detailed test checklist? Or do you have any questions about these testing methods?