How LED Backlights Achieve Uniform Brightness Across Displays

Time : Jan 09, 2026 View : 222

In the field of digital screens, people often rate a display’s quality by how steady its light stays, not just how bright it can get. A screen with bright spots, small flashes, or uneven light looks less professional and trustworthy. Makers of factory tools, medical gear, and upscale home items face a tough task in getting a smooth, steady light. LIGHTBO, a focused company started in 2006, has spent close to twenty years improving LED backlight methods to fix these issues.

The Technical Challenges of Achieving Uniform Brightness

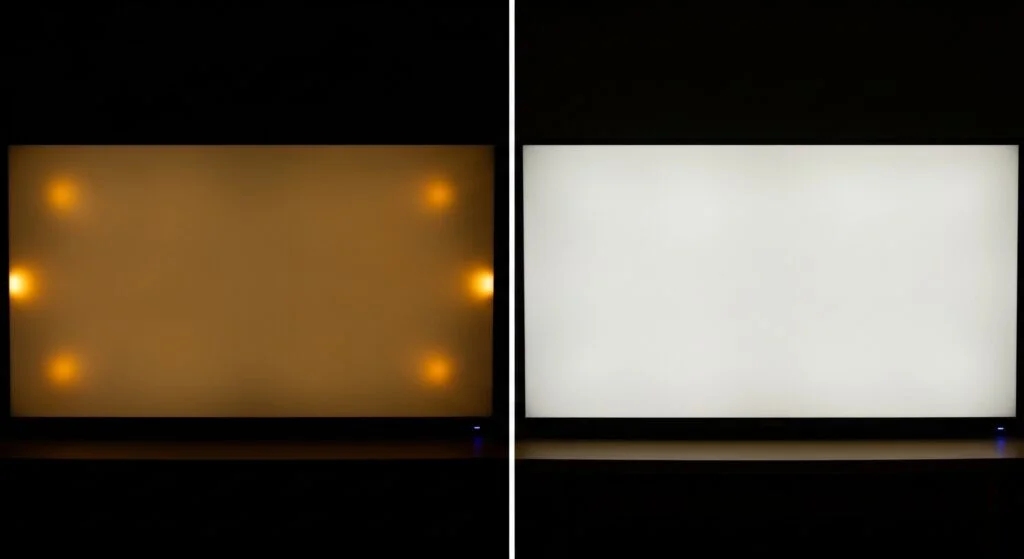

Understanding Light Diffusion and Hotspot Mitigation

Even light across a display means every part gets the same strength of glow, no matter how far from the light source. In basic setups, spots near the LEDs shine much brighter and create annoying hot areas. LIGHTBO handles this with carefully side-lit and full back-lit plans. We use good spreading materials and exact light guide parts. These LED backlight units spread rays smoothly over the whole area. As a result, a 7-Segment LED DISPLAY or a detailed Alphanumeric LED Display stays easy to read from any side.

The Importance of Stable Current and Voltage Management

Uneven brightness often comes from weak power handling. Changes in current can cause tiny flickers that tire eyes and shorten part life. LIGHTBO applies its tech strengths to build units that keep steady light even when power shifts. This works for a 7 Segment LED Display in a UPS system or on an electric scooter screen. Our in-house design group makes sure power connections and drive paths stay reliable. Many choose our parts in instruments, factories, and power areas because of this steady performance.

LIGHTBO‘s Solution: Engineered LED Backlights for Every Application

Precision-Manufactured LED Backlights for Industrial Instruments

Factory settings need screens that read well in bright lights or total darkness. LIGHTBO supplies special LED backlight answers built for long wear and sharp contrast. Our modern auto tools and tight process checks let us make backlights with very close fits. When placed in a control board, the light holds even after years of constant use. This meets the hard needs of factory work.

Customized Color Solutions: From Ultra-Bright White to Pure Green

Each use has its own color needs. A 7 Segment LED Display in a fridge might need Customized Pure Green or Blue shades to give a clean, current feel. On the other hand, Ultra Bright White often works best for oven screens to show clearly through glass in hot settings. LIGHTBO stands out in multicolor changes. We offer many choices, including strong Blue and Pure Green. Matching the LED backlight to the segment color brings bright, even results that common parts can’t reach.

Integrating Backlighting with Specialized Display Components

Enhancing the Clarity of 7-Segment and Alphanumeric Displays

Many interfaces rely on the 7-Segment LED DISPLAY. LIGHTBO has these from single-digit to six-digit types. Paired with our even LED backlight tech, the segments stand out sharply. For needs beyond numbers, our Alphanumeric LED Display in 14 and 16 segments gives room to show clear text guides. The steady light makes sure thin lines in a 16-segment letter glow as strongly as thick ones, avoiding odd looks.

The Role of LED Light Bars and Arrow Displays in Status Indication

Besides letter and number info, quick signs like the LED Light Bar and Arrow LED DISPLAY matter for fast checks. A Multicolor 10 Segment LED Bar often marks levels or steps. Even light here helps users tell the 10 parts apart correctly. An Arrow LED DISPLAY needs to give a plain direction hint. LIGHTBO makes these signs Ultra Bright with high-quality looks that fit the device’s overall style.

SMD LED Displays: Uniformity in Ultra-Thin Form Factors

Devices get smaller these days, leaving less room for screen parts. The SMD LED DISPLAY fits modern thin electronics like e-cigarettes or hand-held medical checkers. LIGHTBO builds Multicolor Ultra Thin SMD types that keep good light despite size. Getting even glow in thin shapes takes extra exact work on the LED backlight layer. Our internal professional design team has handled this well for many world partners.

Manufacturing Excellence: The LIGHTBO Quality Guarantee

Internal Design and Collaborative Product Development

At LIGHTBO, we focus on “Building Success Together. We serve as more than a maker. We act as a partner in growth. Our internal professional design team and modern machinery shop help us cooperate to develop the products you need. If a buyer wants a special shape for an LED backlight or a certain pin setup for a 7 Segment LED Display, we adjust every part of the Electrical terminals beyond the standard demand. This team approach makes the end screen fit the client’s exact case and power setup.

Advanced Automation and Reliability Testing Protocols

Quality forms the base of LIGHTBO’s work. After earning the ISO 9001 quality management system certification in 2015, we have kept adding to automated production equipment and reliability testing equipment. Each LED backlight and display unit goes through hard checks in our professional test lab. They meet RoSH standards and pass supplier checks. This tight quality system helps LIGHTBO hold a top spot in kitchen tools and heat control fields. Buyers rely on us because every piece works with the same even light and steady performance as the first sample.

Conclusion: Why Choosing LIGHTBO Ensures Long-Term Display Stability

Getting smooth and reliable light takes a mix of good materials, careful power design, and modern build steps. LIGHTBO (Shenzhen Guangzhibao Technology Co., Ltd.) has shown leadership by stressing technological innovation, product quality, and excellent service.

We combine our strong LED backlight tech with many items—from 7 SEGMENT LED DISPLAY and Alphanumeric LED Display parts to SMD LED DISPLAY and Arrow LED DISPLAY units. This gives full answers for any visual setup. Our drive for “Pursuing Excellence” means your items will have a high-end, steady light that holds up over the years. In-home tools, new energy, or factory areas, LIGHTBO stands ready to help improve your answers and build your market strength worldwide.

FAQ

Q: How does LIGHTBO ensure there are no “hotspots” in its backlights?

A: We use advanced diffusion materials and edge-lighted light guide plates, combined with precise internal designs, to distribute light evenly across the display surface.

Q: Can LIGHTBO provide custom colors for 7-segment displays?

A: Yes, we specialize in multicolor customization, including Ultra Bright White, Pure Green, Blue, and more, tailored for specific appliances like ovens or refrigerators.

Q: Are your LED displays suitable for high-vibration industrial use?

A: Absolutely. Our products are manufactured using advanced automatic machines and undergo strict reliability testing in our professional lab to ensure stability in industrial and power fields.

Q: Does LIGHTBO assist with the development of new display modules?

A: Yes, our internal professional design team can cooperate with you to develop customized products, including modules with self-developed control programs and capacitive touch.