Displaying Alphanumeric Characters Using 7 Segment LED Technology

Time : Jan 08, 2026 View : 172

In today’s world of digital screens, the straightforward design and sharp readability of LED displays still stand out. You see them everywhere—from the timer on a microwave oven to vital readings on factory equipment. These bright segments deliver information quickly and clearly. LIGHTBO has spent close to twenty years improving this field. The company follows a clear goal of “Pursuing Excellence” and uses modern automated production lines. As a result, LIGHTBO creates display parts that move smoothly from basic numbers to more detailed letter-and-number messages.

The Architecture of 7-Segment LED Technology

A 7-segment LED display is simply a group of light-emitting diodes placed in a pattern that looks like the number “8”. Knowing how these parts work together is the starting point for anyone working with letters and numbers on such screens.

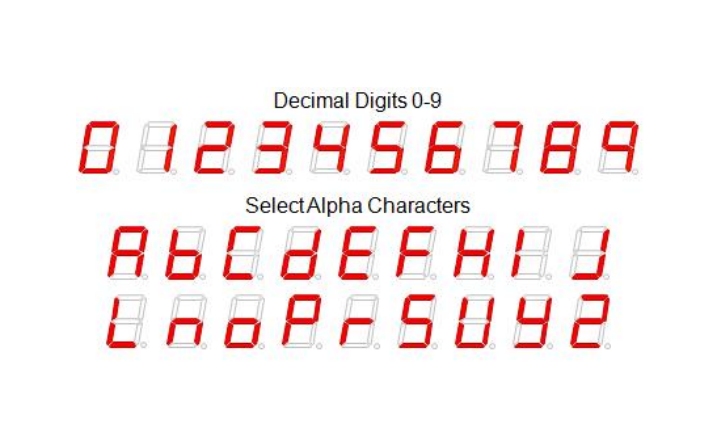

Understanding Segment Mapping: From A to G

A typical 7-segment unit has seven separate bars, marked ‘a’ to ‘g’, plus an extra decimal point if needed. The layout includes three horizontal bars—one at the top, one in the middle, and one at the bottom—along with four vertical bars, two on each side. By turning on the right bars, you can form any digit from 0 through 9. LIGHTBO supplies these setups in many forms, from single-digit units to versions with two, three, or even six digits. This wide choice helps fit different sizes of circuit boards.

Common Anode vs. Common Cathode Configurations

When adding these displays to a project, builders pick between Common Anode and Common Cathode types. In the Common Anode version, all positive ends connect to one power line, and each bar lights up when its negative side is pulled to ground. On the other hand, a Common Cathode unit ties all negative ends to ground, so a positive signal turns on each bar. LIGHTBO makes both kinds available, including multicolor ultra-thin custom cathode displays built for small devices such as e-cigarettes.

Decoding Alphanumerics on a 7-Segment Grid

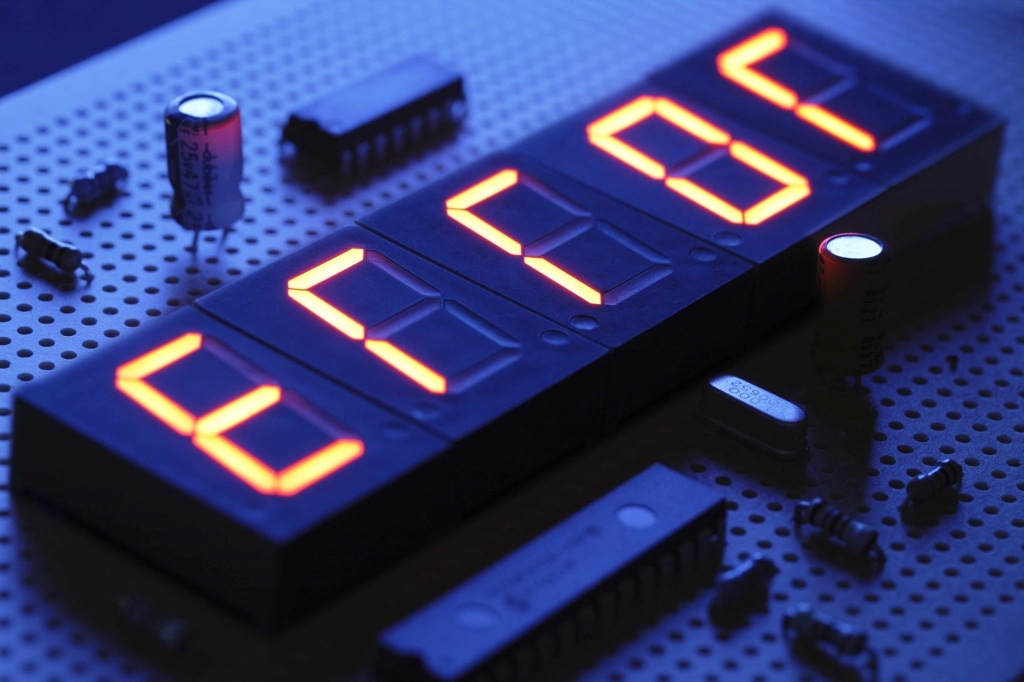

The name “7-segment” suggests numbers only, yet these units can show several letters from the Latin alphabet. This feature proves useful for short status words like “Err” or “On”.

Rendering Numerical Data

The main job of a 7-segment display is to show numbers plainly. Thanks to careful production at LIGHTBO, every bar—whether in a 12.7mm refrigerator unit or an ultra-bright oven model—glows evenly with clean lines. Such uniformity matters greatly in tools where a wrong reading could cause problems.

The Challenge of Alphabetic Representation

The seven-bar layout struggles with letters that need slanted lines or a full middle vertical bar, such as ‘M’, ‘W’, ‘X’, or ‘K. Still, several letters come out well. Common examples include ‘A’, ‘b’, ‘C’, ‘d’, ‘E’, and ‘F’. Designers often use a mix of uppercase and lowercase styles—for instance, a lowercase ‘b’ keeps it distinct from the digit ‘8’. The LIGHTBO technical staff partners closely with customers to fine-tune these letter patterns. This cooperation helps lower production costs while making the final product easier to read and use.

Advancing Beyond the Basics: 14 and 16-Segment Solutions

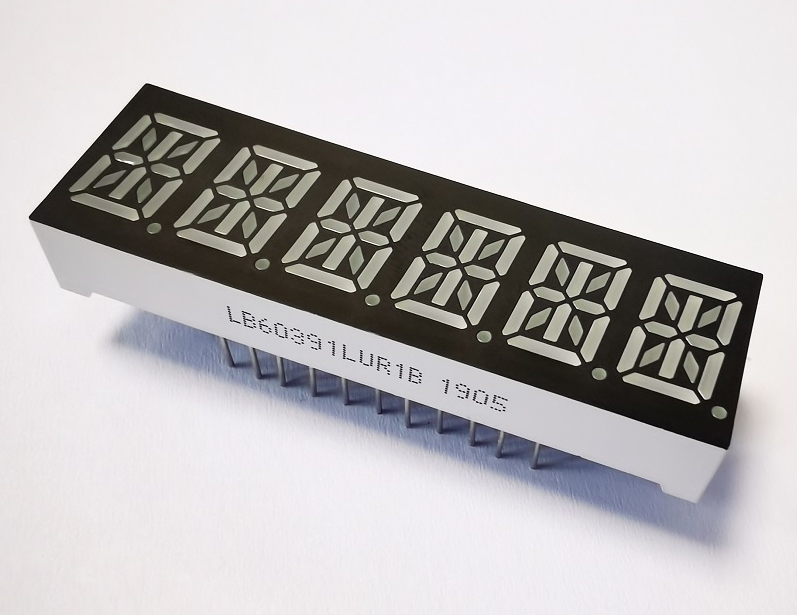

When a device needs to show longer text, like scrolling notes or company names, the standard 7-segment unit grows into a full Alphanumeric LED Display.

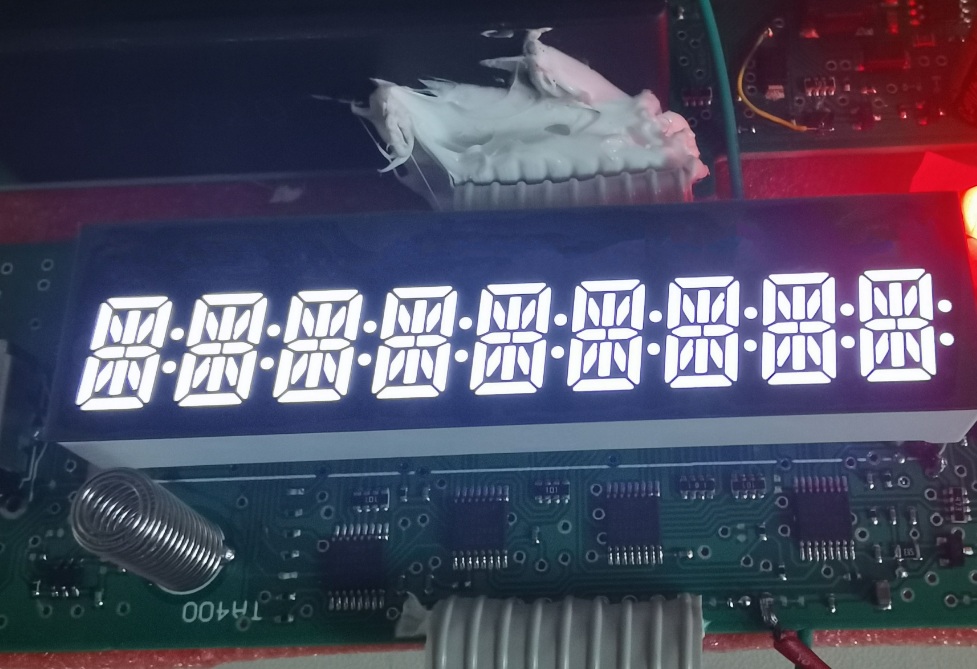

The “Union Jack” Expansion for Complex Characters

To handle the shortcomings of the seven-segment, 14-segment, and 16-segment versions, add slanted bars and split vertical ones. This pattern, sometimes called “Union Jack” because of the crossing lines, makes it possible to form all 26 English letters plus many symbols. Such displays play a key role in advanced instruments and heavy-duty power systems that require detailed messages.

LIGHTBO‘s Specialized Alphanumeric Displays

LIGHTBO stands out as a major supplier of these advanced Alphanumeric LED Displays. The company’s 14-segment and 16-segment models suit places where a lot of information must fit in a limited space. Every unit comes from high-speed automatic machines and passes thorough checks in dedicated test labs. This process meets strict RoHS rules and ISO 9001 standards.

Technical Implementation and Control Strategies

Running an LED display well calls for more than basic wiring. It needs smart control methods and careful board placement.

Multiplexing and Driving Methods

For units with several digits, like LIGHTBO’s four-digit or five-digit models, multiplexing cuts down the number of connections needed from the microcontroller. The system quickly cycles through each digit—so fast that the eye sees steady numbers across the whole display. LIGHTBO has taken this further by creating complete modules with built-in control code and even custom chips. These ready-made parts make final assembly much simpler for device makers.

Surface Mount Technology (SMD) and Modern Integration

As gadgets grow thinner and smaller, the need for SMD LED displays has risen sharply. Unlike older through-hole parts that go through the board, SMD types sit directly on the surface. This allows fast machine placement and takes up far less room. LIGHTBO carries a full line of SMD LED displays that keep the same strong brightness and dependability as traditional models, yet they suit today’s compact products, such as electric scooters and smart home controls.

Application-Specific Solutions and Customization

The real value of LIGHTBO shows in its skill at building parts made for particular uses.

Industrial and Home Appliance Integration

These displays appear in many fields, from kitchen devices to new energy systems and industrial power equipment. For instance, LIGHTBO supplies custom pure green and blue 7-segment units for refrigerators and ultra-bright white versions that handle the heat inside ovens. The company also creates multicolor options for UPS systems, where different colors can signal power status or remaining battery charge.

The LIGHTBO Advantage: Quality and Reliability

Since the start of LIGHTBO in 2008, the focus has stayed on fresh ideas and steady improvement. Key strengths include:

- High Quality: Each item goes through detailed lab testing and follows RoHS guidelines.

- Development: An in-house design group works side by side with clients to create special parts outside normal catalogs.

- Manufacturing: Automated lines brought in during 2016 deliver consistent results and handle large orders smoothly.

Whether the need is an arrow LED display for direction signs or a detailed dot matrix for simple graphics, LIGHTBO makes sure every bar meets the standard of Pursuing Excellence.

Conclusion

Showing letters and numbers on an LED combines basic shapes with practical design choices. The classic 7-segment display remains the go-to choice for numbers and short codes, but the move to 14-segment and 16-segment types has brought richer communication options. As a strong player in this market, LIGHTBO keeps supplying reliable parts and tailored answers that drive displays around the world. From early research to finished production, the company’s drive for new ideas and solid quality means your device interface stays clear, trustworthy, and up to date.

FAQ

Q: Can a 7-segment display show the entire alphabet?

A: No, it can only display a limited subset of letters clearly. For the full alphabet, LIGHTBO recommends using 14 or 16-segment alphanumeric displays.

Q: What is the benefit of choosing an SMD LED display over a through-hole model?

A: SMD displays are more compact and compatible with automated SMT assembly, making them ideal for modern, thin electronic devices.

Q: Does LIGHTBO offer custom colors for specific appliance brands?

A: Yes, we provide multicolor customization, including pure green, blue, and ultra-bright white, to match your specific application requirements.

Q: Are LIGHTBO products certified for international markets?

A: Absolutely. Our manufacturing process is ISO 9001 certified, and our products meet RoHS standards for safety and quality.