Brightness and Viewing Angle Tips for Four-Digit Seven-Segment LED Displays

Time : Jan 01, 2026 View : 219

Introduction: Clarity is King in Digital Readouts

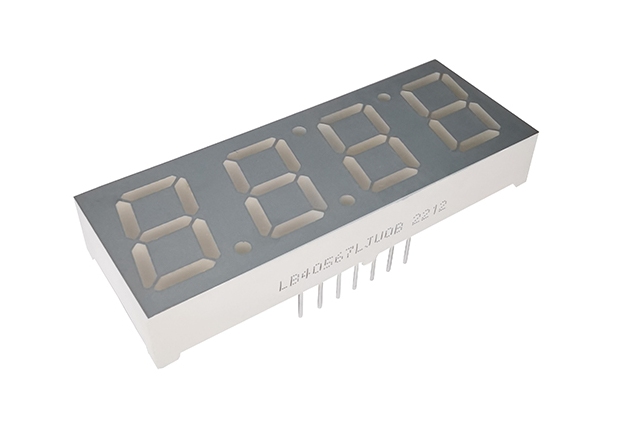

Four-digit seven-segment LED displays handle a lot of everyday digital tasks. They show exact numbers in factory control boards, kitchen timers, and home devices. The basic setup looks straightforward, but good visibility in different lights—from bright sun to dim rooms—comes down to brightness and viewing angle. A screen that is too faint or one that dims from the side can cause mistakes or safety issues.

Engineers and builders need to understand what affects these features to pick the best part. This article covers the main points for a clear readout in four-digit seven-segment displays. It points out how careful manufacturing and custom options from LIGHTBO lead to better results for users.

Fundamentals of 4-Digit Display Performance

Why Four Digits Dominate Precision Readouts

People choose four digits often because the range goes up to 9999, with room for decimal points or signs. That fits many needs, like temperature readings in ovens, settings on tools, or countdowns on clocks. LIGHTBO makes a complete line of 7 Segment LED Displays, from single digit up to 6 digits or more with customized solution, with a strong focus on the popular Four Digit types. Starting with a solid, well-made four-digit unit sets the stage for clear numbers.

The Twin Pillars: Brightness and Viewing Angle Defined

Brightness, or luminous intensity, measures how much light comes from each segment. It decides if the numbers stand out in strong surrounding light. Viewing angle covers the area where the display maintains good contrast and light level. A strong design holds clear digits even from sharp sides.

These factors connect closely. Spreading light wider for better angles can lower the straight-on brightness a bit. Good displays find the right mix for the place they go.

Achieving Optimal Display Brightness

Good brightness matters for easy reading. Too low, and numbers vanish; too high, and it tires eyes or uses extra power.

Selecting the Right Color and Intensity

Different colors need different currents and give varied light levels. For spots needing strong visibility, color choice counts. LIGHTBO offers custom 7-segment LED displays in several shades, such as:

-

Ultra Bright White: Works well in places wanting sharp contrast, like the Ultra Bright White Custom 7 Segment LED Display for oven panels.

-

Pure Green or Blue: Often picked for tools or looks, as in the Customized White/Pure Green/Blue 7 Segment LED Display for fridge units.

-

Multicolor: Handy for status signals, including the Multicolor customization 7 Segment LED Display For UPS or the Multicolor Ultra Thin Custom 7 Segment LED Display Cathode For E-cigarette.

Builders should set the light output to match the light around the final product.

Driving the Display: Multiplexing and Peak Current

Many four-digit units run on multiplexing. Only one digit lights at a time, switching fast so all look on. To keep average light steady, the short burst of current to each digit runs much higher—usually 4 to 8 times the normal level, based on cycle time.

High bursts create heat and can shorten life if not handled correctly. Makers like LIGHTBO build units to take these loads safely. Tight steps in production keep things reliable.

Ensuring Brightness Consistency Through Quality

In big batches, light differences between units cause problems. LIGHTBO keeps things even with careful steps and checks. We stress HIGH QUALITY through a tight control system and our own test lab. Thorough checks make sure every four-digit part matches in light strength and shade, cutting issues for buyers.

Maximizing Usable Viewing Angle

Wide angles let numbers stay sharp from different spots. This helps in factory panels or car dashes, where people view from various positions.

The Impact of Physical Encapsulation

The package shape and material around the LED chips shape the angle the most. The epoxy or resin spreads and directs light. Builders control their form and mix carefully. Using Advanced automatic machines and strict process checks helps get an even light spread over a broad range.

Addressing Glare and Contrast Ratios

In sunny spots, the contrast between lit parts and background decides readability more than raw light. Reflections cut clarity. Ways to help include dark backgrounds and shaped reflectors inside.

LIGHTBO has a skilled in-house team for custom work. Our DEVELOPMENT edge comes from modern shop tools. We work with customers to tweak these details for tough light conditions.

Customization for Off-Axis Requirements

Some uses need special angles.

-

Fixed spots like ovens: Can use a narrower up-down angle since viewers stand straight most of the time.

-

Changing views like meters: Need a broad side-to-side angle for fields in Instruments, Industrial, and Power.

LIGHTBO excels at custom builds. We adjust chip placement, reflector size, and material clarity to meet exact side-view needs for special setups.

LIGHTBO Solutions for Professional Applications

LIGHTBO started in 2006. The company handles research, making, and sales of display parts. We follow the idea of “Pursuing Excellence, Building Success Together” with a focus on new ideas and solid service.

Precision Manufacturing for Consistency

Our strength shows in careful making and checks. With LIGHTBO four-digit seven-segment displays, teams gain from this focus:

-

HIGH QUALITY: We meet rules like RoSH and test in our lab for steady electrical and light specs over the years.

-

MANUFACTURING: Modern machines and tight controls keep package and segment sizes the same. This matters for even light and angles across digits.

Application-Specific Design and Customization

Our work covers home devices, tools, and new energy fields. We tailor brightness and angles to fit. For example, the Multicolor Ultra Thin Custom 7 Segment LED Display for E-cigarette needs a small size and close-view angles. Fridge customs handle cold without fading. This skill makes products work well where placed.

Conclusion: Designing for Readability and Longevity

Four-digit seven-segment LED displays remain key for clear numbers. Good brightness and angles are must-haves for trust and use. Careful current handling in multiplexing and solid build for light spread gives top performance. Working with LIGHTBO, strong on checks, customs, and modern making of 7 Segment LED Display lines, builds the base for sharp, lasting readouts in any setting.

FAQ

Q: What is the main drawback of maximizing brightness by drastically increasing peak current?

A: Excessive peak current, even if managed by multiplexing, can reduce the overall lifespan of the LED die and lead to premature degradation of brightness.

Q: How does LIGHTBO ensure the color of the display (e.g., White vs. Pure Green) is consistent across batches?

A: LIGHTBO maintains a strict quality control system and utilizes a professional test lab to verify specifications, ensuring consistent color and luminous intensity in its displays.

Q: What is the typical application environment for the Ultra Bright White Custom 7 Segment LED Display?

A: The Ultra Bright White Custom 7 Segment LED Display is frequently tailored for high-visibility applications like controls in household appliances, such as Ovens.

Q: Does the viewing angle calculation change if the display is surface-mounted (SMD)?

A: While the physical encapsulation factors change (often being lower profile), the core principle of maintaining contrast and uniform light emission across the required spatial cone remains the same for SMD LED DISPLAYs.