7 Segment VS 14 or 16 Segment Alphanumeric: Choosing the Clearer Pressure Readout

Time : Dec 18, 2025 View : 282

The Critical Choice: Display Readability in Electronic Pressure Switches

Walk onto any factory floor, and you’ll see pressure switches everywhere—on air lines, hydraulic presses, water pumps, you name it. The sensor inside does the hard work, but the little screen on the front is what the operator actually looks at all day. Miss a reading because the numbers are fuzzy or the message is confusing, and you’ve got downtime, scrap parts, or worse. So the question every designer asks is simple: do we stick with the tried-and-true 7-segment display that just shows numbers, or go alphanumeric(14 or 16-segment) so the switch can spell out what’s really going on?

The Mandate for Clarity in Industrial Automation

Plants are loud, dusty, and the lights swing from bright sun through a skylight to dim corners at night. Vibration from machines makes cheap screens flicker. You need something the technician can read from three meters away while wearing gloves and safety glasses. One glance should tell him “150 psi” or “SENSOR FAIL” without stopping to squint or grab the manual.

Defining Readability: Speed, Accuracy, and Environmental Tolerance

Good readability boils down to three things. First, how fast can the brain grab the info? Second, how often does someone misread a 5 for an S? Third, does the screen still look sharp in steam, cold, or under fluorescent lights that buzz at 60 Hz? Get those wrong and the whole switch becomes a headache.

Technical Foundations: Anatomy of Segmented Displays

LIGHTBO has been building LED displays since 2006 in Shenzhen. We make everything from plain 7-segment digits to full dot-matrix panels and backlights. Knowing how the segments work helps pick the right one for a pressure switch.

The Simplicity and Constraints of the 7-Segment Display

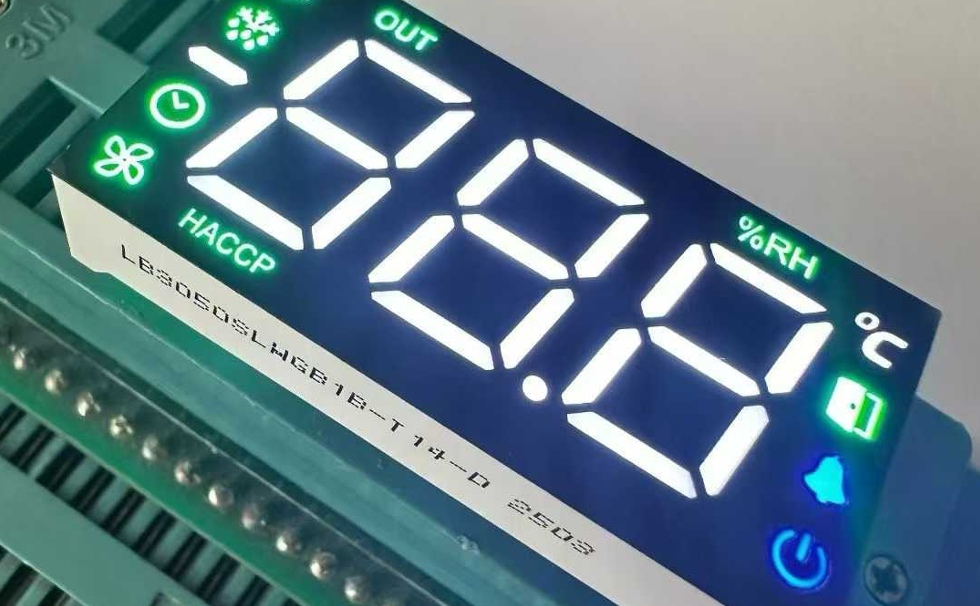

A 7-segment digit is just seven bars plus a decimal point. Turn the right bars on, and you get 0–9 or some simple letters clean and quick. Add a few more digits, and you can show 0.1 psi resolution or six-figure set points. We do single-digit all the way to six-digit versions, common cathode or anode, whatever the circuit board needs. Want pure green numbers that punch through factory haze? We’ve got the Customized White/Pure Green/Blue 7 Segment LED Display 3 Digit 12.7 mm ready to drop in.

It’s cheap, bright, and dead reliable for plain numbers. The catch? Try spelling “CAL” or “ERR,” and it looks like a bad game of Hangman. You can fake a few letters (C, O, E), but most come out confusing. For basic “show me the pressure” jobs, nothing beats it.

The Expressive Power of 14 and 16 Segment Alphanumeric Displays

When numbers alone won’t cut it, we move to 14-segment or 16-segment characters. In addition to the numbers 0-9, extra bars let every letter A–Z show up clearly, plus punctuation and symbols. Suddenly, the switch can flash “HOLD”, “PSI”, “BAR”, “OVERPR”, or “SENSOR BAD” without any guesswork. LIGHTBO stocks both 14 SEGMENT LED DISPLAY and 16 SEGMENT LED DISPLAY parts in all the usual sizes and colors.

Readability Comparison in Pressure Switch Applications

Pure Numerical Data: Where 7-Segment Displays Excel

If the switch just needs to sit there and spit out “68.3 bar” all day, 7-segment wins hands down. Big, bold digits are easier to read at a glance than tiny letters. One maintenance guy told us he can spot a drifting reading on a 7-segment switch from across the aisle without stopping his cart—try that with letters, and he’d have to walk over every time.

Displaying Status, Units, and Errors: The Need for Alphanumeric (14 or 16-Segment) Detail

Smart switches do more than count pressure—they talk. They tell you when calibration is due, when the sensor is dirty, and when the output is locked. Trying to cram “LOW BATT” into a 7-segment looks like “LO bRtt,” and nobody knows what that means at 2 a.m. Alphanumeric(14 or 16-segment) spells it out in plain English (or German, Spanish, whatever). Downtime drops because the tech fixes the right problem the first time.

The Impact of Brightness and Customization on Industrial Readability

We’ve seen switches mounted under sodium lights that wash everything orange, or outside in –30 °C, where cheap LEDs go dim. That’s why we push ultra-bright parts and let customers pick pure green for daylight or deep red for night shifts. Throw in our LED backlight options, and the numbers stay punchy no matter what.

LIGHTBO’s Commitment to High-Performance Display Solutions

LIGHTBO started in 2006, and we’ve stuck to one idea: make displays that just work, day after day. You’ll find our parts in washing machines, EV chargers, and plenty of factory gauges.

Comprehensive Product Range for Industrial Instruments

Need a three-digit 7-segment that reads crystal clear in steam? Done. Want a 16-segment that spells “FAULT” in 20 mm letters? Got it. We keep stock of the common stuff and build the odd sizes in-house fast.

LIGHTBO’s Manufacturing and Quality Assurance Advantage

Everything runs through our own test lab—burn-in ovens, vibration tables, the works. We’re RoHS clean and carry all the usual paperwork. Parts leave the line only when they pass, period.

Strategic Selection: Matching Display Type to Application Needs

When Simple Numerical Output Suffices

Basic switch, one pressure value, maybe a set point—go 7-segment. Cheaper, brighter, and impossible to misread the number.

When Complex Feedback is Non-Negotiable

Anything with menus, units, error words, multiple languages—alphanumeric(14 or 16-segment) is the only sane choice. The extra few cents per unit saves hours of head-scratching later.

Conclusion: Choosing Clarity for Safety and Efficiency

Numbers and simple letters only? 7-segment every time. Need Complete A-Z and words too? 14 or 16-segment. Either way, LIGHTBO has the exact part—bright, tough, custom if you need it. Pick the one that matches the job, and your operators will thank you every shift.

FAQ

Q: What are LIGHTBO’s main strengths?

A: Rock-solid quality (own test lab, RoHS), fast custom work (in-house design team), and real factory muscle (auto lines, tight process control).

Q: Do you make displays just for gauges and meters?

A: We specialize in many displays designed for instruments, industrial equipment, and power systems, and can often provide solutions for other applications as well.

Q: What alphanumeric options do you have?

A: Full line of 14-segment and 16-segment displays, any size or color.

Q: Can a 7-segment be made stupidly bright?

A: Absolutely—ultra-bright white, pure green, blue, whatever punches through factory light.